Performance. Technology. Safety.

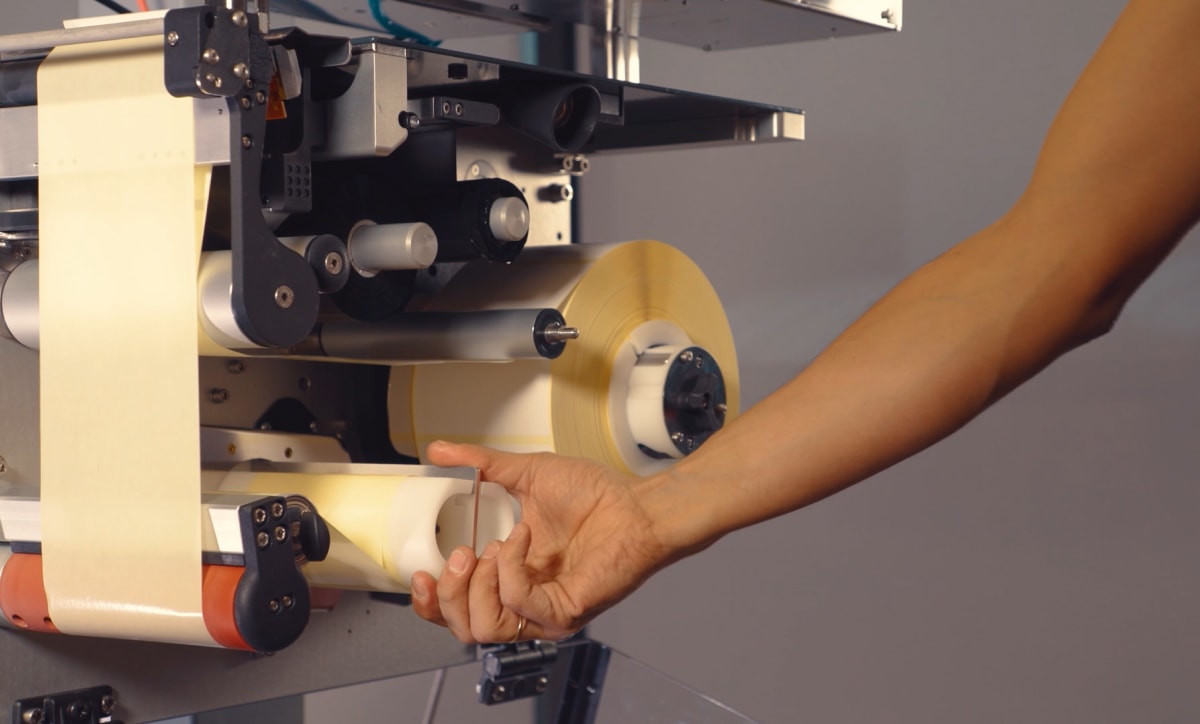

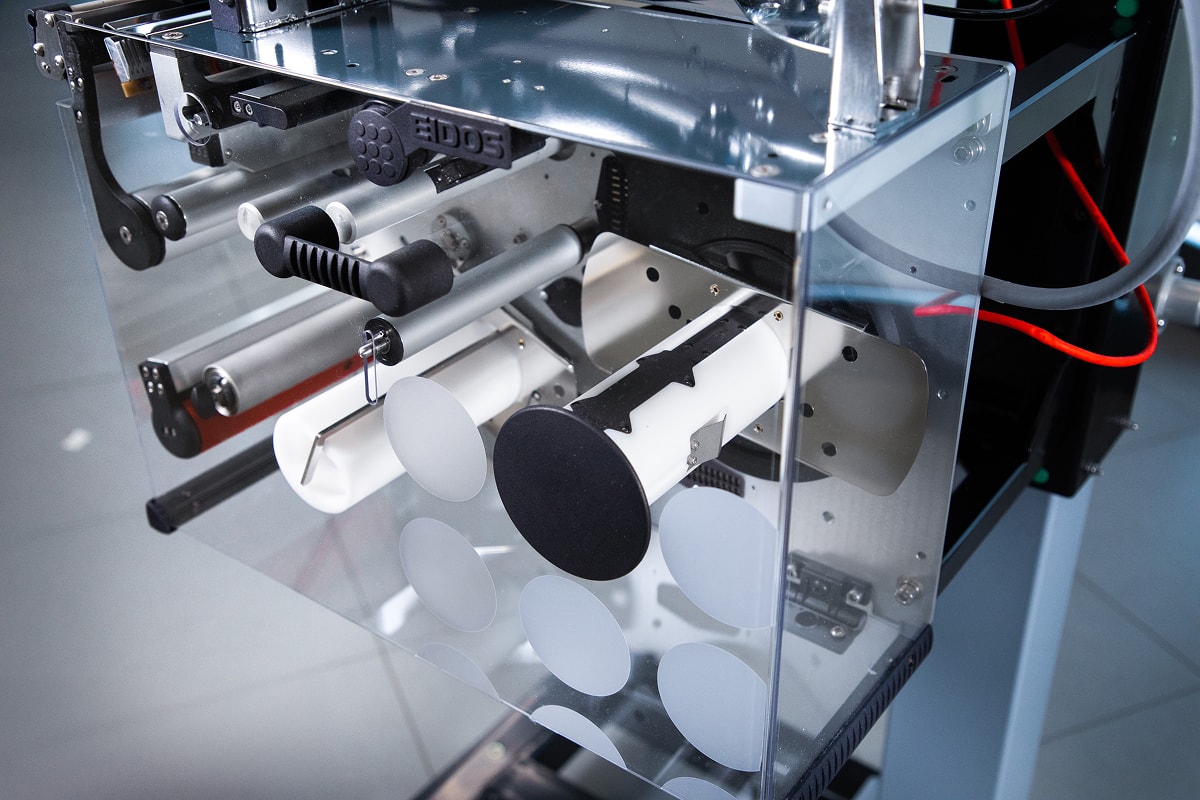

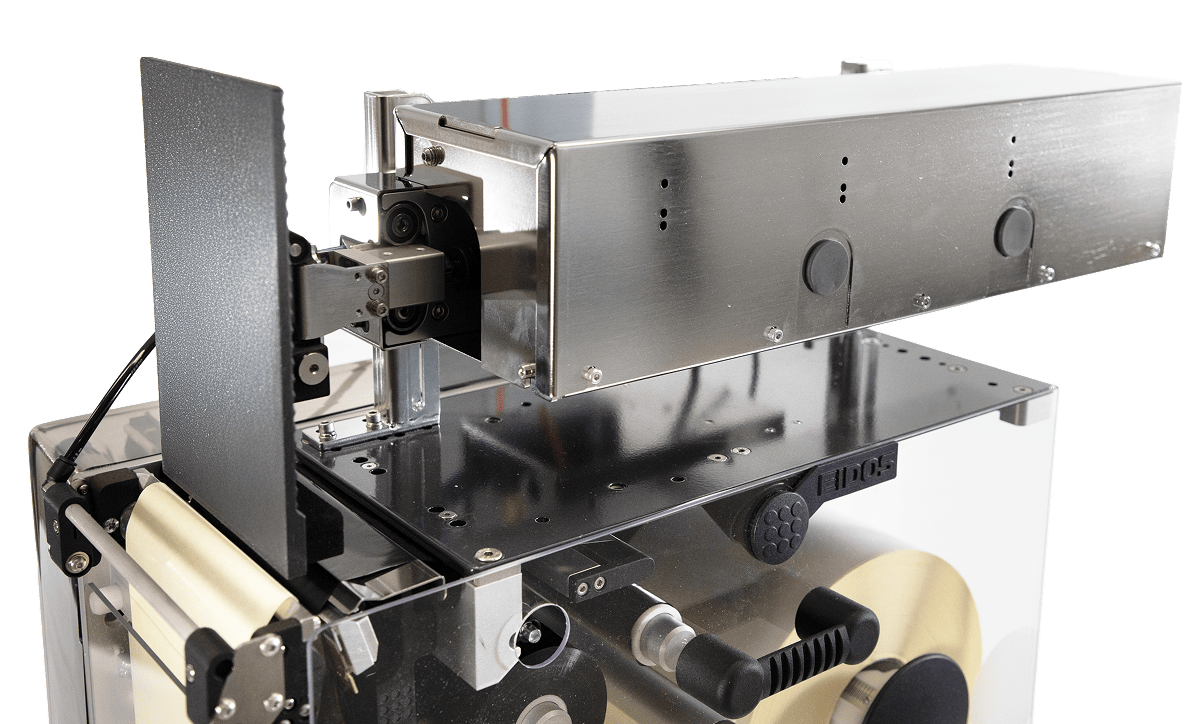

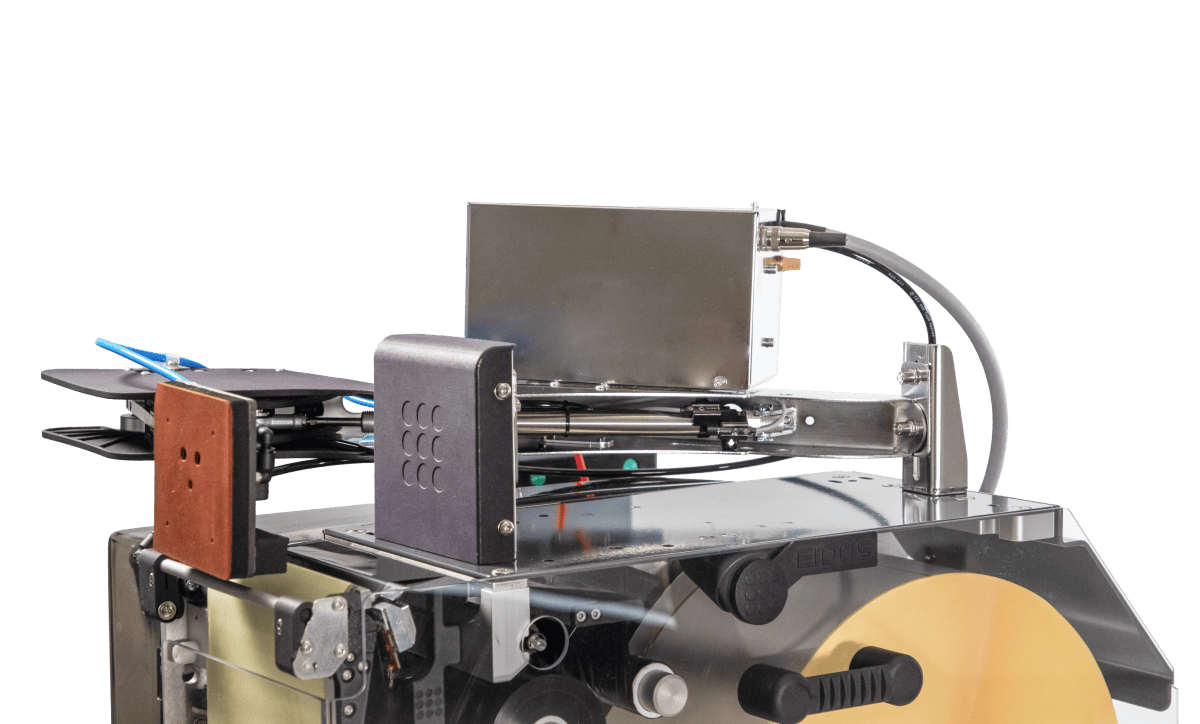

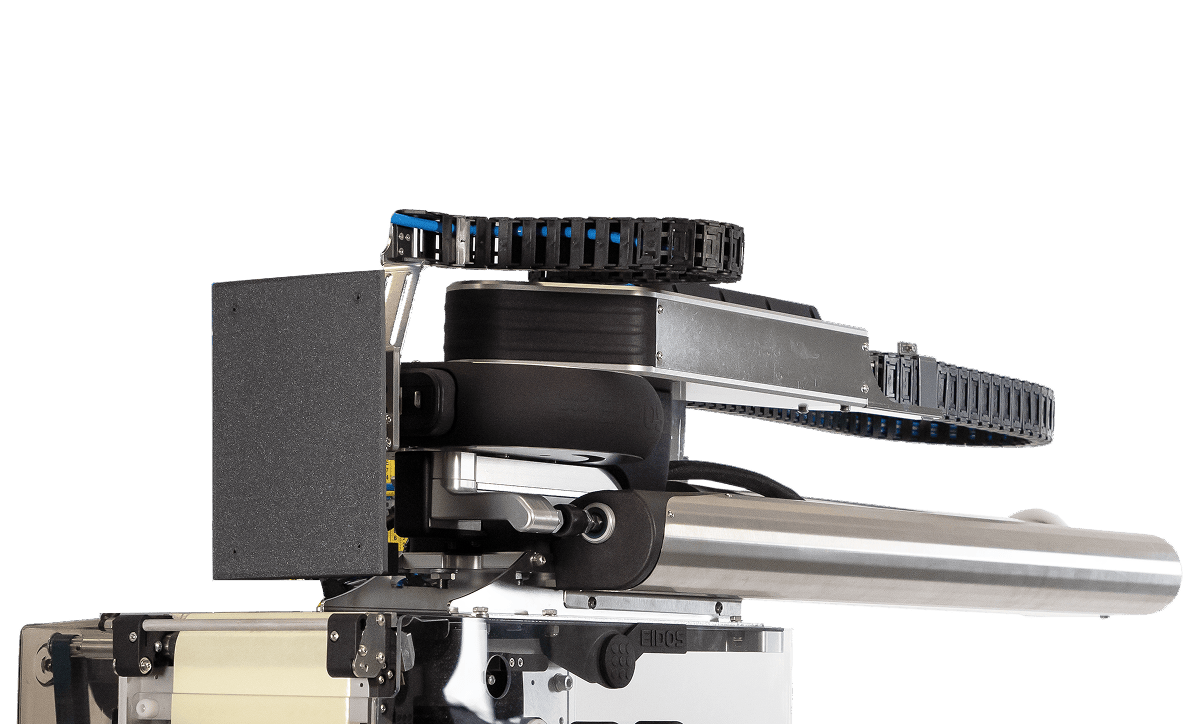

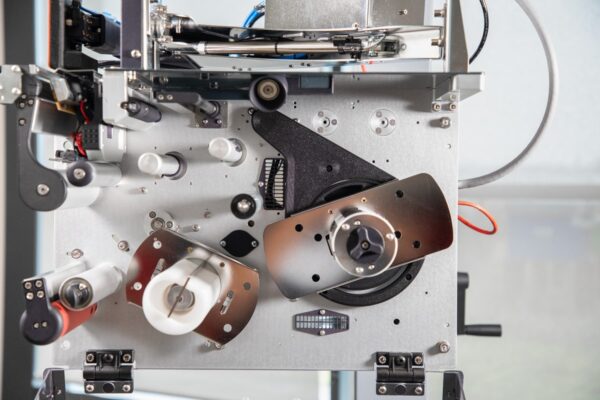

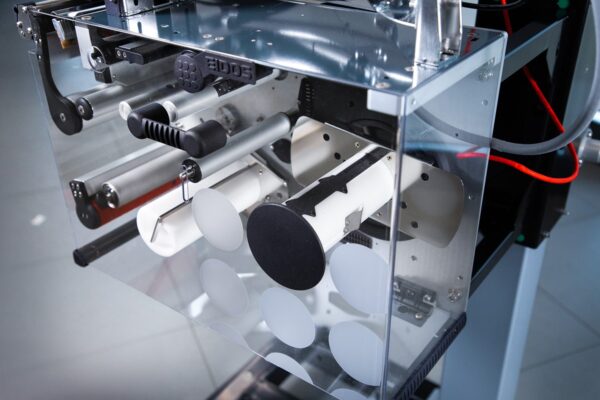

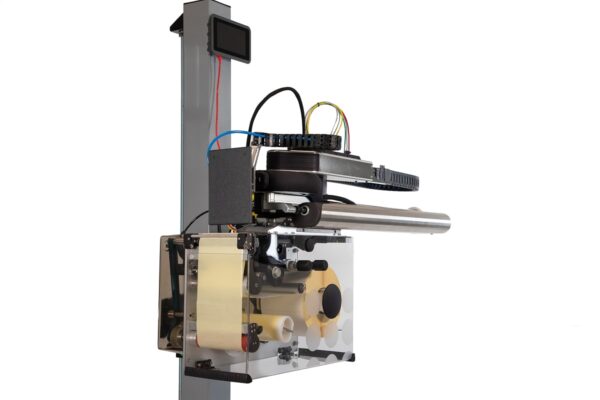

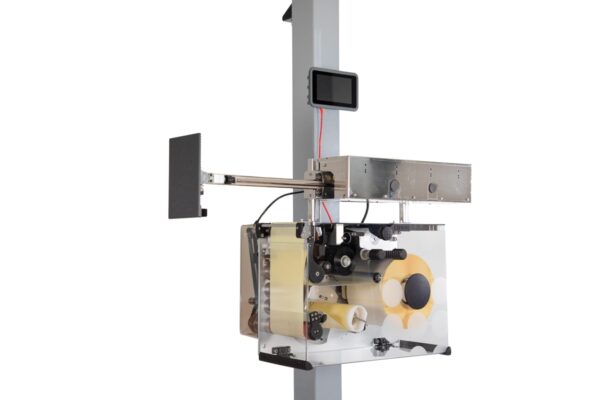

The new PTS is the sixth generation of Print & Apply systems developed by EIDOS. It was born to meet the growing demands for flexibility, reliability and speed in label printing and application in modern production environments.

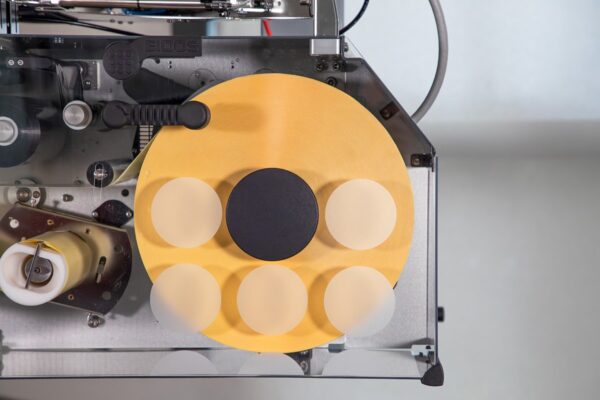

Derived from the winning concepts of TTO (Thermal Transfer Over-printer) technology for flexible packaging, but completely rethought for Print & Apply, PTS combines ergonomics, modularity and high performance in a single compact and intelligent machine.

More than a machine: it is a platform designed for the future.